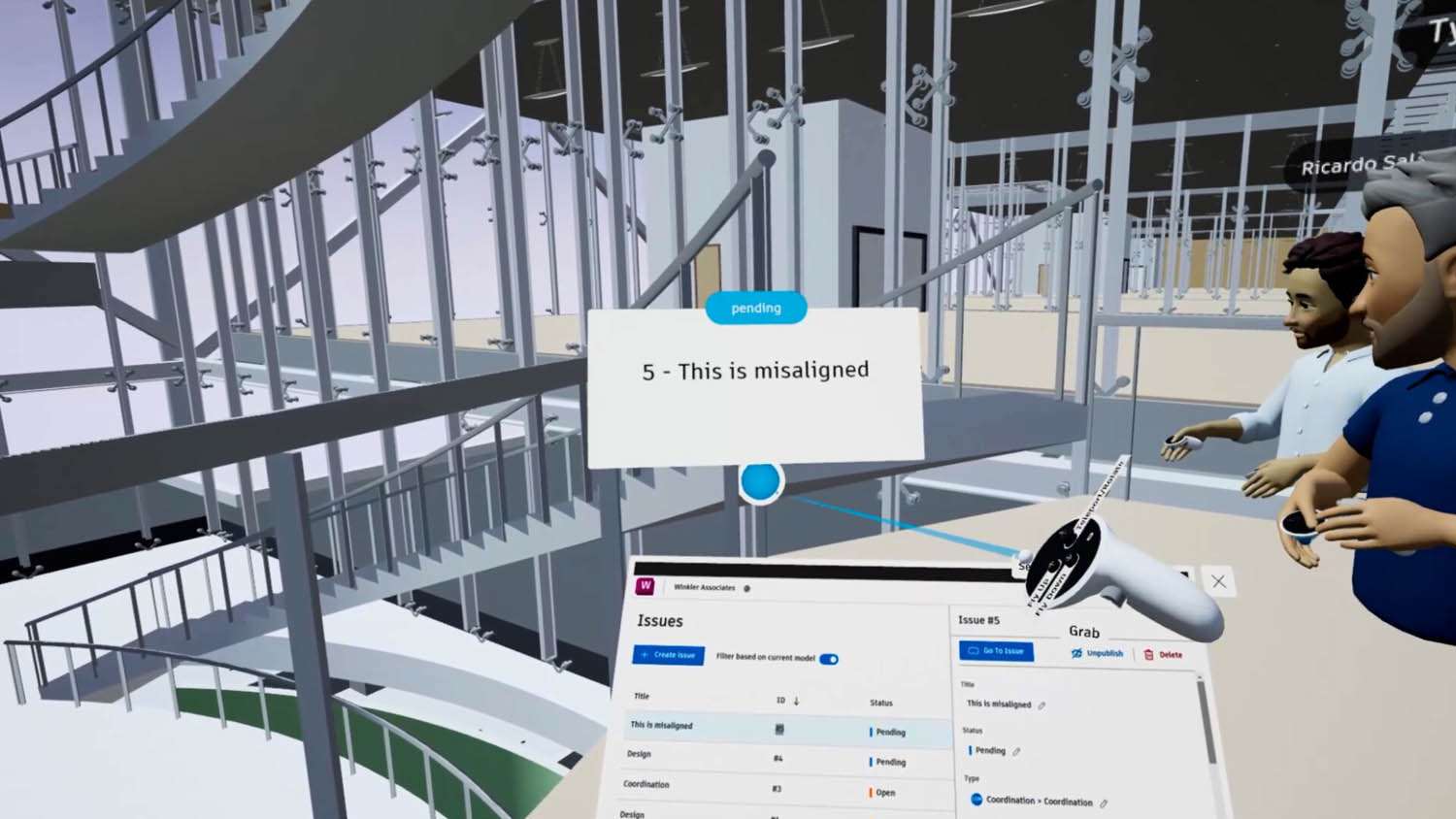

With Workshop XR, AEC teams can review and collaborate on projects to track issues, catch errors, and gain a better spatial understanding of the design. With ‘automatically connected’ data from ACC, there is no need to prep models. Issues are automatically synced and tracked with ACC, with a view to making design reviews ‘frictionless and efficient’.

Multiple disparate users can collaborate in the Workshop XR workspace using standalone VR headsets. These are connected directly to the platform via WiFi. Depending on the location of the user within the BIM model, relevant 3D model data is streamed to the device and cached. All of the rendering is done locally on the headset.

For the best experience, Autodesk recommends the Meta Quest 3, but the Meta Quest 2 and Meta Quest Pro are also supported. While the initial focus is solidly on VR, there are plans to broaden support to other hardware devices. There is a functional desktop app in beta, which will potentially be released as a tech preview. There are also plans for mobile, including the Apple iPad.

Currently, teams can collaborate in VR to solve ACC issues. Alternatively, when design errors are found in VR, users can create ACC issues through a familiar ACC interface. Users get direct access to all BIM information, properties, and metadata.

The current focus is on Navisworks and Revit models, but Autodesk intends to broaden the types of formats and files that are supported in Workshop XR.

Workshop XR is a natural evolution of The Wild, the AEC cloud connected XR platform that Autodesk acquired in 2022.

According to Nicolas Fonta, the main difference with Workshop XR is its deep connection to Autodesk Construction Cloud.

The Wild offers integration with Autodesk BIM 360, but this is done by syncing workspaces and models. Whenever a new Revit, Navisworks or other 3D file is published to BIM 360, data is automatically pulled in.

“The source of truth for Workshop XR is your projects as they reside on ACC,” says Fonta. “It means that there is no need to wait between the time where you want to start a review session and actually being in a headset.

“It means what you’re creating, building and doing in Workshop XR does not go into a separate repository on the side in a different format. Everything you do, for example issues, it doesn’t create a Workshop XR issue, it goes and creates an ACC issue. And similarly, anything that happens in ACC is viewable and accessible in our XR solution.”

In order for ACC data to be readily available for XR consumption in VR headsets, Autodesk has spent a lot of time focusing on the data pipeline. This will also have a benefit beyond XR, as Fonta explains, “We also want to optimise the data pipeline at Autodesk in general for viewing. So, what we’re doing is optimising everything and streamlining, so we’re streaming just the pieces that are relevant to the experience and to the user in the VR headset, with the intention of reusing those capabilities across the board at Autodesk on our platform to optimise utilisation and data access.”

Fonta told AEC Magazine that 600 million poly models have been successfully loaded into Workshop XR, but this is only the beginning as he explains, “We intend to continue the optimisation of our data pipeline so that ultimately, we could put in and send any model size to Workshop XR to be used and experienced.

“To be clear, we’re not saying that you will see the entire model at all times; what we’re saying is that we’re optimising for the experience based on where the user is, so that the relevant data (or where the person is located) and the use case or the task at hand and what they’re trying to do, will be available.”

Workshop XR cost $1,075 for a yearly subscription. AEC firms will also need to invest in ACC, although as Fonta points out there are many different levels. “Smaller firms might stick to the basic ACC and not go with things like takeoffs and all of the other products.

Workshop XR also comes with a free entitlement to Autodesk Docs. “You won’t give you the full fledge capability and all the bells and whistles but at least you’ll be able to connect, share with peers and do the basics,” says Fonta.

Stantec Finds New Flow with XR

While deep in production work and late nights for a hospital tower project, Jon Matalucci at Stantec, a global leader in sustainable design and engineering, decided to try VR as an experiment. It immediately became an a-ha moment.

“One night before our Friday BIM call, I was pushing views to prepare the design review of the hospital tower project and thought, ‘Well, there’s a plugin in Navisworks for Prospect by IrisVR. Let me see what I can get back out of it,’” says Matalucci, a BIM and virtual design and construction manager. “Boy, that was my eye-opening experience. I could see things like electrical outlets floating in glass and exit signs down on the floor. It was immediately apparent to me that the team’s current workflow would benefit from this tool.”

At the time, the firm often used VR for presentations. But after that virtual design review, Matalucci never looked back. He immediately added VR as his go-to tool and integrated it into his workflow.

“There’s a perception that there is a project scale when you use visualization tools,” Matalucci says. “What we realized is that VR works on every project. From day one, we could start moving through the projects and process. VR became an opportunity to reduce the silos and work more efficiently.”

Experiencing new benefits

With VR reviews in Stantec’s everyday workflow, there are less meetings, less emails, and less back and forth. “Our meetings went from being an hour long down to 15-minute touchpoints and the meeting groups got smaller and smaller,” Matalucci says.

Collaborative design reviews provided new efficiencies. Anyone can pop into the model any time—even stakeholders. During one project, it was difficult to schedule night-shift nurses for their feedback. Matalucci and his team sent them a link to access the model in VR instead. After one VR meeting with the nurses on a Monday, all the feedback and design comments were done and incorporated by Friday.Even with the benefits, challenges in VR remained. It could take hours, sometimes days to prep the model for loading. Alignment across the platform and software was also difficult, for instance, understanding the source of truth. But, for Matalucci, the time savings, collaboration, and error reduction always far outweighed these factors.

“I’m constantly being tasked with exporting, pre-processing, and setting things up. Autodesk Workshop XR helps to keep those workflows together and enable further compression of the schedule. For example, it would take 3-4 hours per week to line up processing for two large projects at 400,000 square feet each. Now it’s streaming and directly connected to models. That is fantastic.”

– Jon Matalucci, BIM and virtual design and construction manager, Stantec

Autodesk Workshop XR delivers new ways to work

With the debut of Autodesk Workshop XR, Matalucci is putting new features and enhancements directly into action—many of which are solving his previous challenges.

Usability within Workshop XR is key as they previously relied on a web interface and manual transfer of information. Now a console “pops up” and allows him to browse, open, and review files immediately.

The ability to work with files from Autodesk Construction Cloud (ACC) is one of the most exciting advancements from his own BIM/VDC manager’s standpoint. The familiarity of the interface and using the software will help others in the company to readily use VR. He also sees real time savings by integrating team members in ACC.

Common data environment

“Before Workshop XR, if we had issue tracking as a separate activity, I’d often have to reintegrate it with other issues and then bring it all back into ACC,” Matalucci says. “It just slowed everyone down. With Workshop XR, our teams can now work in parallel, share the same information in a common data environment, and view and interact with all the different data sets and file types. It’s immeasurable in value.”

Some of Stantec’s projects are intricate healthcare projects. That means large, complex models—and it took a long time to prep and load for VR. By moving to Workshop XR from Prospect by IrisVR, there is no prep and the entire model is available to explore.

“It always required a dedicated amount of time to prepare the model,” Matalucci says. “I’m excited that all I have to do is grab my headset now, put it on, and I’m in there.”

At the end of the day, Matalucci believes Workshop XR is all about better workflow—with the emphasis on “flow.”

“We always use the word workflow in the industry,” he says. “But we can tend to focus on the ‘work’ and forget about the ‘flow.’ ACC has been incredibly productive for us. Working with both Workshop XR and ACC and seamless model loading without all the prep, we finally have that ‘flow’ piece going.”